Product

Lithium battery production line

Automatic production line of lithium battery

Service NetworkNational Service Hotline400-990-6600

Lithium battery equipment consultation telephone:13817653150Product Description

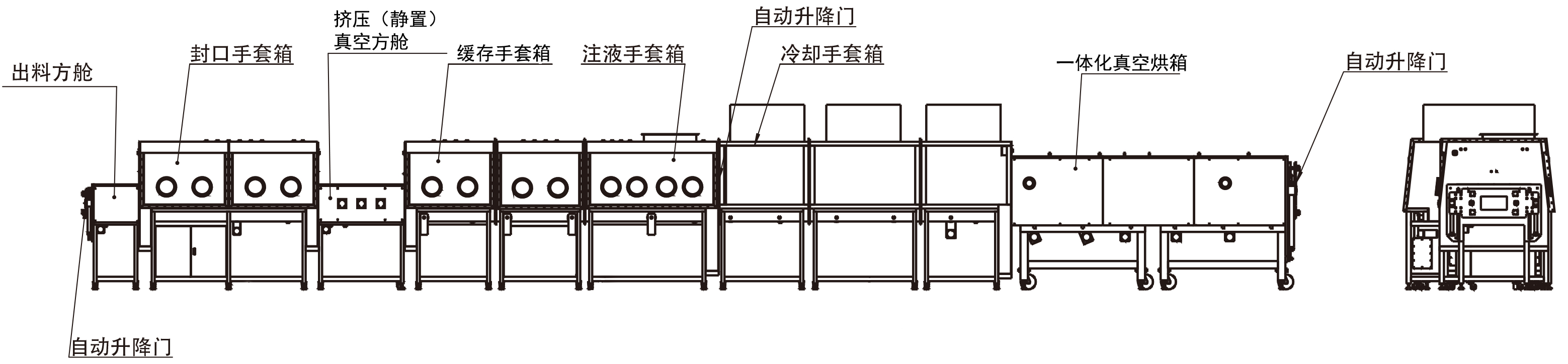

The integrated production line consists of oven, cooling glove box, liquid injection glove box, buffer glove box, extrusion (standstill) vacuum shelter, sealing glove box and discharge vacuum shelter. The electric core realizes automatic transmission in the above-mentioned operation.

The function of the oven is to realize the vacuum drying of the battery. The function of the cooling glove box is to cool down the battery. The function of the glove box is to provide a water-free and oxygen-free operating environment, in which liquid injection and sealing operations are completed.

The oven and the cooling glove box are seamlessly connected to ensure continuous production in a controlled, water- and oxygen-free environment. All square cabin doors are automatically opened and closed, controlled and operated by Siemens PLC touch.

Advantages of integrated lithium battery production line:

1. The oven and the glove box are seamlessly connected to achieve continuous production

2. Fast cooling speed

3. Operation environment without water and oxygen

4. Automatic transmission and other functions

5. MES manufacturing execution system

6. Low cost

|

|

|

work process:

1. Put the battery into a vacuum oven for baking, and vacuum to minimize the battery moisture.

2. The baked battery automatically enters the cooling glove box through the conveying device, and the cooling glove box has a cooling device to quickly cool the battery.

3. The cooled battery can gradually and automatically enter the liquid injection glove box for liquid injection through the conveying device.

4. After liquid injection, the battery enters the buffer glove box.

5. The battery in the cache glove box enters the squeezing (standstill) vacuum cabin to squeeze the battery.

6. After squeezing (resting) the vacuum shelter, the battery will automatically enter the sealed glove box after being vacuumed to seal the battery.

7. The battery comes out through the discharging cabin, and the entire conveying process of the battery can realize automatic transmission.

|