Product

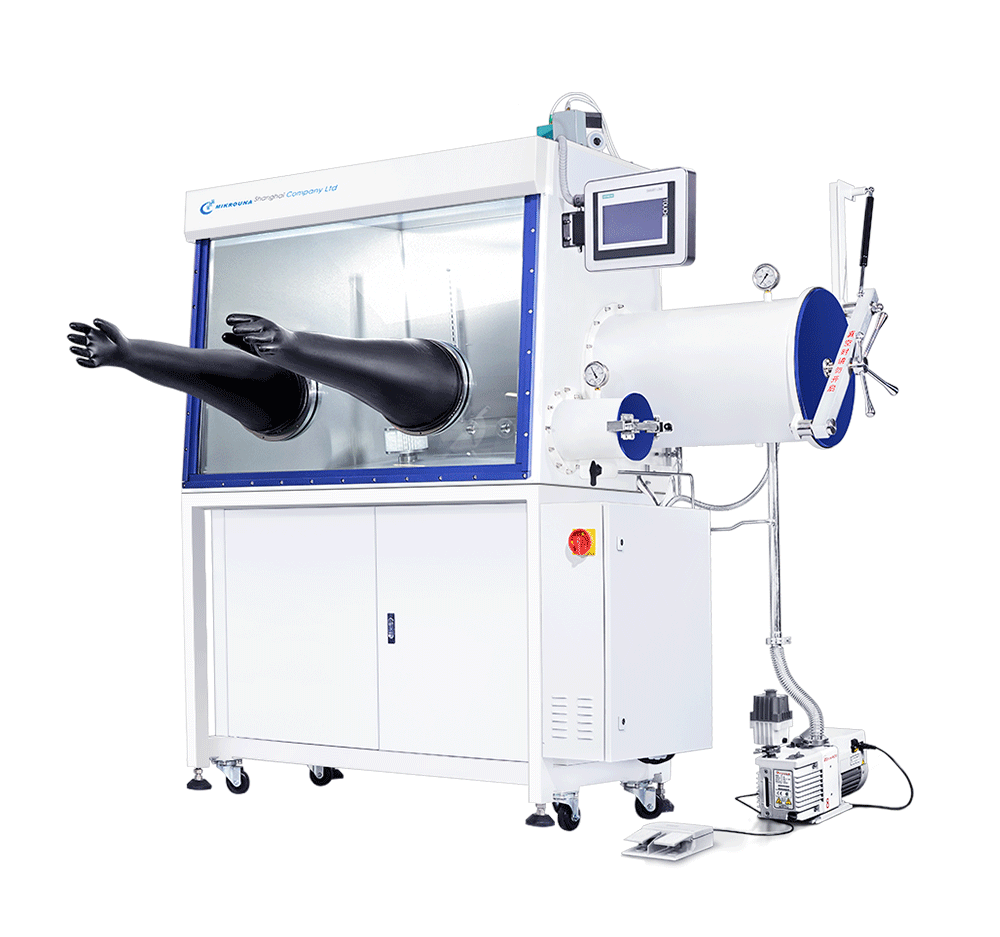

Flange Window Glove Boxes O-ring Vacuum Sealing

Flange window with vacuum seal

National Service Hotline400-990-6600

|

|

|

|

Super(1220/750/900) |

Super Pro(1220/750/900) |

Pro(1220/750/900) |

|

· Flange window "O" seal structure

· Circular big/small transition bin

|

· Flange window "O" seal structure

· Rectangular big/small transition bin

· Manually operated door

|

· Flange window "O" seal structure

· Rectangular big/small transition bin

· Automatic door

|

|

Features and Advantages of O-Ring Flange Window:

|

|

1. The window flange is of rectangular ring cut from a whole piece of thick plate for high strength and resistant to impact, extrusion and deformation, with sealing groove to be slotted. 2. The whole flange window and ring sealing groove are formed in one step in the large gantry machining center.

3. The flatness of the sealing support surface and the bottom surface of the sealing groove is <0.1 mm/m.

4. The flange window and the box adopts continuous welding mode, with non-destructive testing adopted to detect the weld, and there is no leakage in the welding. It adopts the vacuum sealing mode of embedding the integrated "O-shape" sealing ring into the ring-shape groove without seams on the sealing ring, for high sealing reliability, low leakage rate, and box leakage rate of <0.0006vol%/h.

5. Suitable for sealing of windows and doors of vacuum equipment.

|

|

Disadvantages of Traditional Window

|

|

1.No Flange, No Sealing Grooves: The supporting surface is formed by bending and splicing of the chamber plates with poor flatness and weak support. And the O-ring is glued on the support surface. 2. Sealing Method: The hollow O-ring is placed between the glass and supporting surface. 3. Hollow O-Ring: By the compression deformation of the hollow O-ring, the unevenness of the support surface gets compensated. The hollow diameter is around 2~4mm, some poor-quality O-ring is up to 10mm. And there are wrinkles after the O-ring is pressed which leads to a high leakage rate and unreliable sealing. 4. A kind of simple mechanical sealing, not a vacuum sealing. 5. Applicable for sealing of large thin-walled parts whose sealing surface cannot bemachined, or for simple sealing of non- vacuum equipment without quality requirements. |