Exhibition

Exhibition information | Mikrouna invites you to attend China Nuclear Energy High Quality Development Conference and Shenzhen International Nuclear Power Industry Expo

2022-12-07

from:

Time and place of the meeting

Location: Shenzhen, Guangdong

Time: November 15 to November 17, 2022

Background

The 2022 China Nuclear Energy High Quality Development Conference and Shenzhen International Nuclear Energy Industry Innovation Expo (hereinafter referred to as "Shenzhen Nuclear Expo") will be grandly opened in Shenzhen International Convention and Exhibition Center from November 15 to 17, 2022!

With the theme of "Nuclear Gathering in the Bay Area, Energizing the World", this Nuclear Expo is co sponsored by China Energy Research Association, China Guangdong Nuclear Power Group, Shenzhen Development and Reform Commission, and co sponsored by China Nuclear Power Group, Huaneng Group, Datang Group, State Power Investment Group, and State Energy Investment Group, During the same period, more than 10 high-quality conference clusters and a series of major theme activities will be held to build a world-class exchange platform in the nuclear energy field, which will cover key exhibitors and exhibits in the upstream, middle and downstream of the industry chain Relevant leaders and experts of scientific research institutions gathered together to discuss the high-quality development plan of nuclear energy, draw a blueprint for sustainable development of nuclear power, and gather industry wisdom for the development of nuclear power industry in China and even the world.

Mikrouna has a booth in this forum. Interested scholars and experts are welcome to come to the booth for exchange and guidance!

About Mikrouna

Shanghai Mikrouna Electromechanical Technology Co., Ltd

01 High tech talents

Mikrouna has a professional product research and development team, with more than 100 engineering and technical personnel, including 2 researchers (professor level senior engineers) and more than senior engineers.

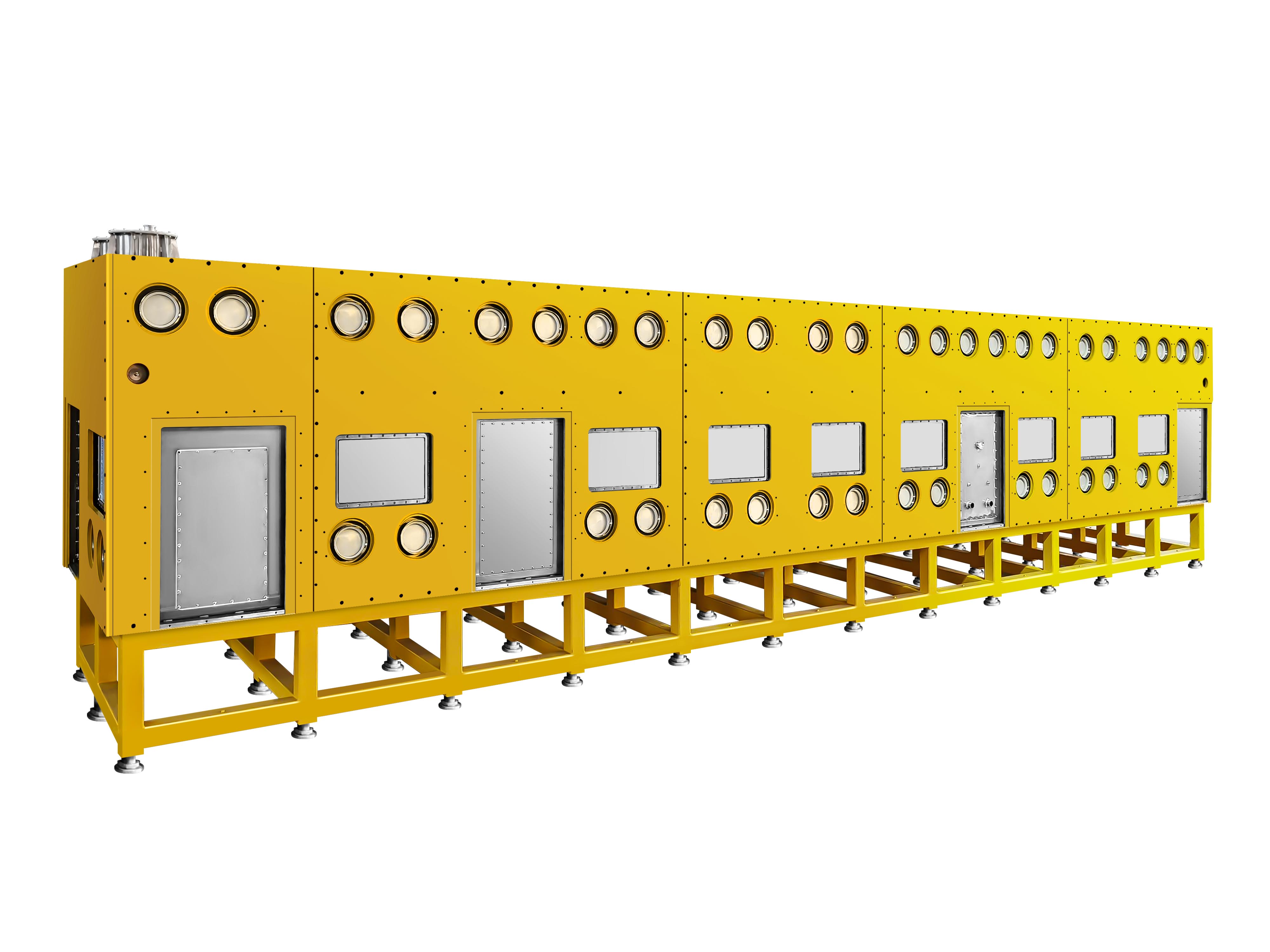

02 Specialized products

Now the production range covers isolation glove box/vacuum box products, protection/protection glove box products, laser cutting and welding machines, automation products, Internet of Things industrial intelligent products, high-end intelligent equipment and other products. These high-end equipment are widely used in lithium battery R&D and production, physical and chemical research, powder metallurgy, nuclear technology, biological pharmacy, special welding, OLED, material processing Fine chemical industry and other industries.

03 Technical achievements

It has nearly 100 patented technologies, one major national research and development project, and many high-tech achievements.

04 Worldwide service

Mikrouna products are distributed all over the world, with multiple service centers, and research and development centers in Shanghai, Hubei, and Shenyang.

Application area

New products

O-ring vacuum sealing flange window

O-ring, "0" leakage

Disadvantages and Disadvantages of Traditional Windows

- No flange, no sealing groove: 3mm box plate is bent and spliced on four sides to form a support surface, with poor flatness and weak support strength. The sealing ring is pasted on the surface of the support surface. The plate is too thin, easy to deform and unreliable.

- Sealing method: a hollow sealing ring is placed between the pressing plate and the supporting surface, and the unevenness of the supporting surface is compensated by the compression deformation of the hollow sealing ring. Generally, the hollow diameter is 2-4mm, and some poor manufacturers reach 10mm; After the sealing ring is compressed, there are wrinkles on the surface, so the leakage rate is high and the sealing is not reliable.

- It is not a vacuum seal, but a simple mechanical seal.

- The sealing ring has interfaces and is easy to leak.

- It is suitable for simple sealing of large thin-walled components and non vacuum equipment with extremely low requirements whose sealing surfaces cannot be machined.

"O" type "vacuum seal" flange window features

- The window flange is cut into an integral rectangular ring by using an integral thick plate, with high strength, impact resistance, extrusion deformation resistance, and sealing groove can be opened.

- The integral flange window and annular sealing groove are formed by a large gantry machining center with one knife. The flatness of the sealing support surface and the bottom surface of the sealing groove is less than 0.1mm/m.

- The flange window and the box shall be welded continuously, and the welds shall be inspected by nondestructive testing, and there shall be no leakage at the welding point.

- The vacuum sealing mode in which the integral annular "O" type sealing ring is embedded into the integral annular groove is adopted. The sealing ring has no joint, high sealing reliability, low leakage rate, and the box leakage rate is less than 0.0006vol%/h.

- It is suitable for sealing windows and doors of vacuum equipment.